Redefine Vision & Intelligence

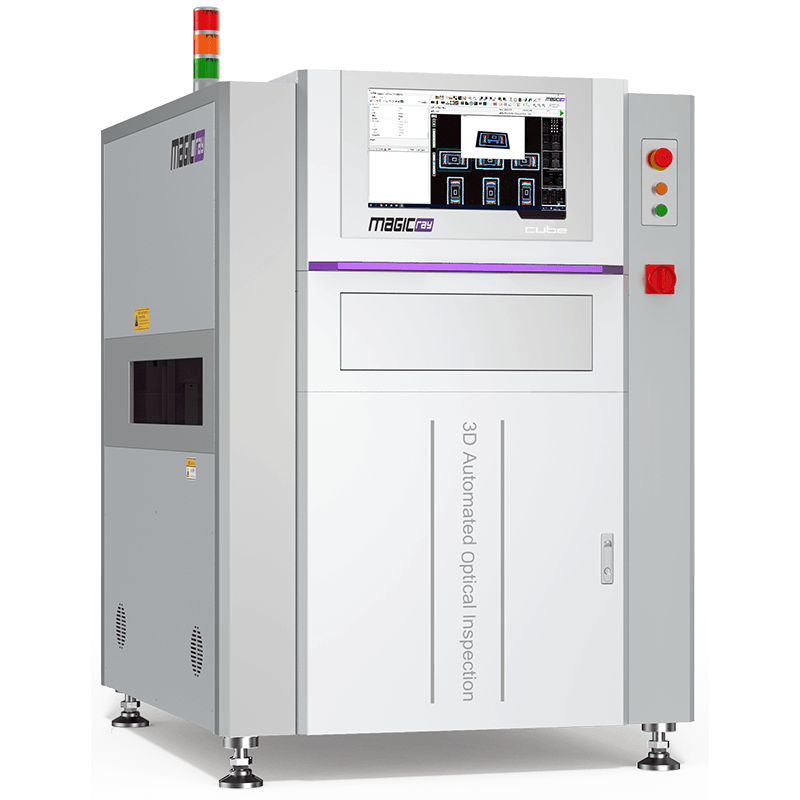

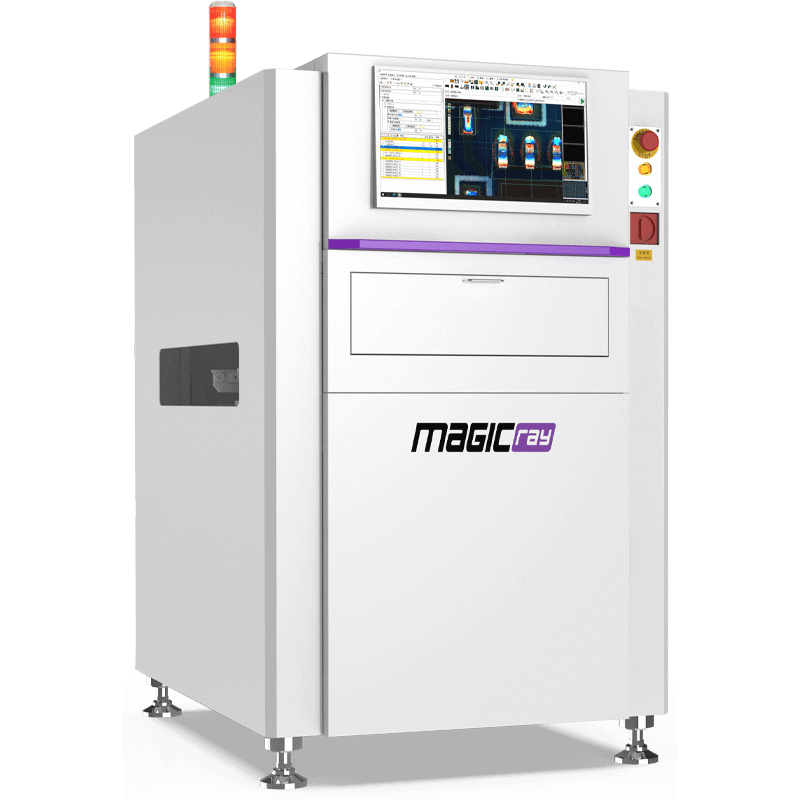

Cube Series

Cube Series

Rich algorithm, the combination of 3D, Al and color feature algorithms to optimize the detection rate of the defects.

Multiple positioning methods to locate the component precisely. Intelligently compensate for board warpage and detect defects on black components on black board.

Adapts to different color PCBs, effectively detect both black and white boards.

Marble platform, dual-drive plus motion control card ensure industry-leading inspection speed.

Ultra-high range 3D reconstruction technology, capable of measuring components up to 35mm height.

The powerful combination of three-point check software and SPC data analysis quickly identifies the root cause of defects.

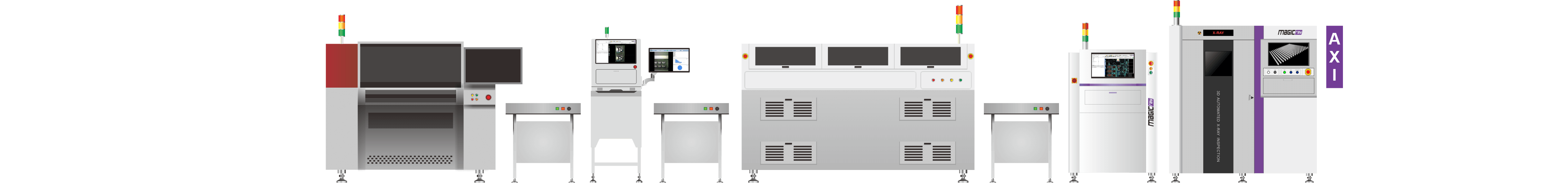

V5000 Series

V5000 Series

Use of granite platform and telecentric lens.

Powerful software algorithm makes inspection very reliable.

Automatic compensation for board warpage or PCB deformed by high temperature effects make our machine just as suitable for FPC.

SPC data analysis helps to improve process quality.

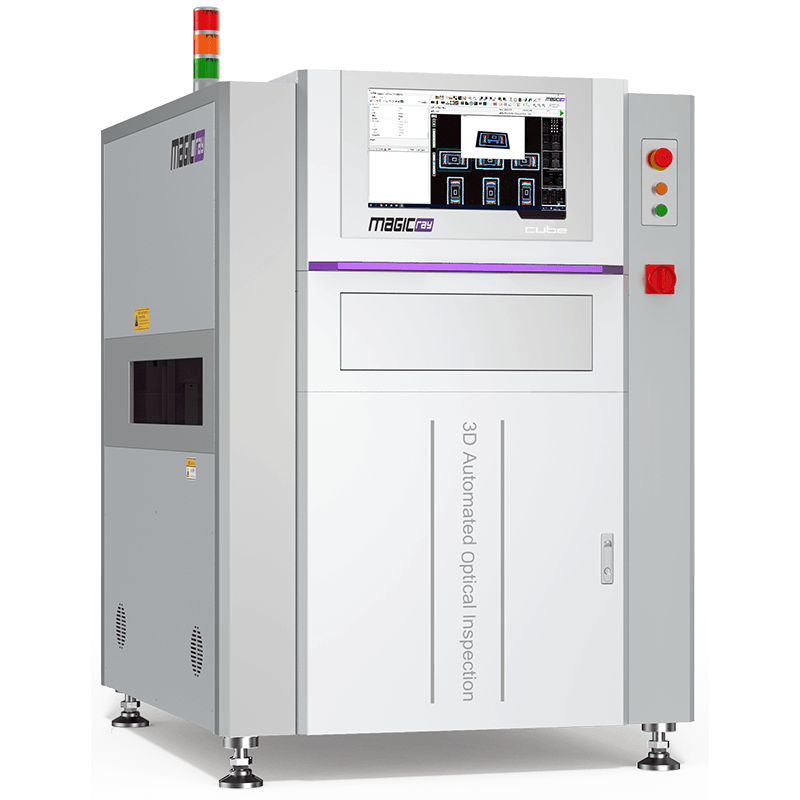

Cube Series

Cube Series

Rich algorithm, the combination of 3D, Al and color feature algorithms to optimize the detection rate of the defects.

Multiple positioning methods to locate the component precisely. Intelligently compensate for board warpage and detect defects on black components on black board.

Adapts to different color PCBs, effectively detect both black and white boards.

Marble platform, dual-drive plus motion control card ensure industry-leading inspection speed.

Ultra-high range 3D reconstruction technology, capable of measuring components up to 35mm height.

The powerful combination of three-point check software and SPC data analysis quickly identifies the root cause of defects.

V5000 Series

V5000 Series

Use of granite platform and telecentric lens.

Powerful software algorithm makes inspection very reliable.

Automatic compensation for board warpage or PCB deformed by high temperature effects make our machine just as suitable for FPC.

SPC data analysis helps to improve process quality.

V5300 Series

V5300 Series

Unique feature is its ability to inspect on both sides of the pcba simultaneously saving production floor space and investment.

Pulley type conveyor can be selected vs the standard Belt Type , the former more resistant to high temperature, dirt and heavy loads.

MagicRay’s proprietary Solder Pad Positioning Algorithm and FOV Assisted positioning makes detection of components more accurate.

CPU-specific algorithm for pins accurately captures various defects such as pin bending, pin deformation and missing pins.

V5100 Series

V5100 Series

Abundant algorithms, capable of detecting SMT, wave soldering and special-shaped components.

Al minimal programmming, one-click generation of components and solder joint inspection windows, automatic identification of component polarity.

Belt or wheel drive, easy to deal with oversized and overweight circuit boards.

Wide range of applications, can be flexibly used for pre-furnace or post-furnace inspection.

Oriainal marble base with anti-seismic and anti-shake functions to ensure stable operation of the equipment.

V5200 Series

V5200 Series

Powerful algorithm logic for post wave soldering inspection of SMT and odd shape components.

Fast programming, auto-generate thru hole inspection window with one-click function.

Automatic compensation for PCB deformed by high temperature effects makes our machine just as suitable for FPC.

Optical fiber sensor is featured to trigger board drop alarm.

Pulley type conveyor is more resistant to high temperature, dirt and heavy loads.

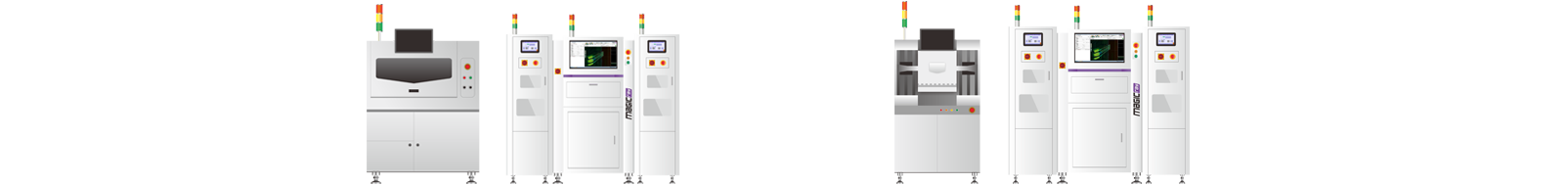

VF5100/VF5300

VF5100/VF5300

Five sided inspection, with full coverage around the components.

Automatically draw side adhesive contour lines to clearly distinguish adhesive boundaries.

Slide mouse to view the percentage of climbing height at any position of side of the component.

Save images of five sides and test data to facilitate process review.

Optional thickness measurement function to achieve inline measurement of adhesive thickness.

VC5300 Series

VC5300 Series

Usage of high-brightness Uv lighting, easily distinguishes the coating containing phosphor.

Support intelligent programming of detection areas across FOV and of components across CADadapative to multiple inspection scenarios.

Support Single-side or Double-side inline automatic inspection of conformal coating.

Coating Thickness Measurement is optional, realizing real-time high-precision thickness measurement.

Optional intelligent Al algorithm optimizes detection on bubble deffects.

VC5000/VC5100 Series

VC5000/VC5100 Series

Usage of high-brightness Uv lighting, easily distinguishes the coating containing phosphor.

Support intelligent programming of detection areas across FOV and of components across CADadapative to multiple inspection scenarios.

Support Single-side or Double-side inline automatic inspection of conformal coating.

Coating Thickness Measurement is optional, realizing real-time high-precision thicknessmeasurement.

Optional intelligent Al algorithm optimizes detection on bubble deffects.

SW6000 Series

SW6000 Series

Designed for power component packaging post die and wire bonding defect detection.

Combined 2D camera & 3D structured light image capture for rapid inspection.

Compatible with conveyor track to allow for inline testing and features offline testing with automatic loading and unloading.

Al powered smart programming vastly improves programming efficiency.

Completely offline programming capabilities - debugging without stopping production.

Flexible lighting and adjustable Z axis easily handle complicated inspection situations.

Links with MES systems, supports TCP/IP, SECS/GEM communication protocols and more.

Advanced SPC capabilities support data review and process analysis.

SW2000 Series

SW2000 Series

For the inspection of semiconductor packaging after D/W and W/B process.

High speed, high reliability: Granite platform + Linear motor + Three-section buffer structure.

Adjustable z axis: the program automatically adjusts the z axis.

High precision: 12 megapixel industrial color camera + low distortion telecentric lens.

Full-auto magazine loader & unloader of large capacity.

Offline programming and debugging in real-time without stopping the production line.

Detection of covered gold wire, copper wire, aluminum wire and palladium-plated copper wire.

Support uploading MES for Mapping.

NG material mark.

Vacuum suction platform for warpage and flexible PCB.

SW6000 Series

SW6000 Series

Designed for power component packaging post die and wire bonding defect detection.

Combined 2D camera & 3D structured light image capture for rapid inspection.

Compatible with conveyor track to allow for inline testing and features offline testing with automatic loading and unloading.

Al powered smart programming vastly improves programming efficiency.

Completely offline programming capabilities - debugging without stopping production.

Flexible lighting and adjustable Z axis easily handle complicated inspection situations.

Links with MES systems, supports TCP/IP, SECS/GEM communication protocols and more.

Advanced SPC capabilities support data review and process analysis.

SW2000 Series

SW2000 Series

For the inspection of semiconductor packaging after D/W and W/B process.

High speed, high reliability: Granite platform + Linear motor + Three-section buffer structure.

Adjustable z axis: the program automatically adjusts the z axis.

High precision: 12 megapixel industrial color camera + low distortion telecentric lens.

Full-auto magazine loader & unloader of large capacity.

Offline programming and debugging in real-time without stopping the production line.

Detection of covered gold wire, copper wire, aluminum wire and palladium-plated copper wire.

Support uploading MES for Mapping.

NG material mark.

Vacuum suction platform for warpage and flexible PCB.