Magic-ray safeguards industrial automation production with high-speed, high-precision, powerful, and user-friendly visual inspection solutions, ensuring reliable and efficient manufacturing processes.

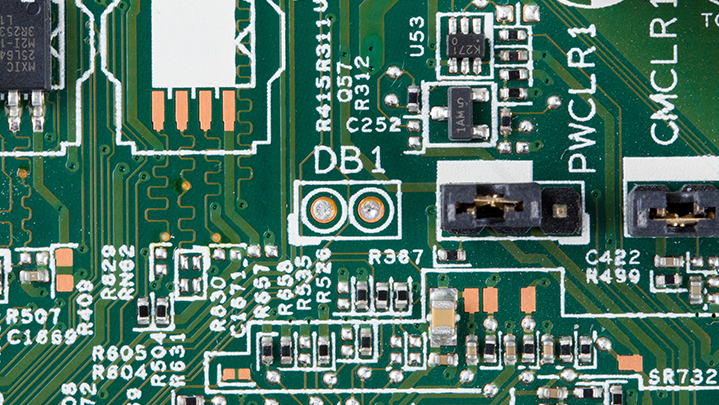

The equipment combines a powerful imaging system with flexible and sophisticated logic algorithms to comprehensively inspect various defects, including wrong part, missing part, reverse, offset, various solder joint defects, and foreign object, duplicate, and solder ball on the entire PCB.

3D technology enables clear detection of height-related defects. Double-sided AOI inspects both sides of the PCB with SMT and DIP algorithms. SPI solder paste inspection catches most defects early in the production line. The multi-functional conformal coating AOI inspects the quality of UV coating layers and also supports SMT and THT inspection.

* 合作代表客户

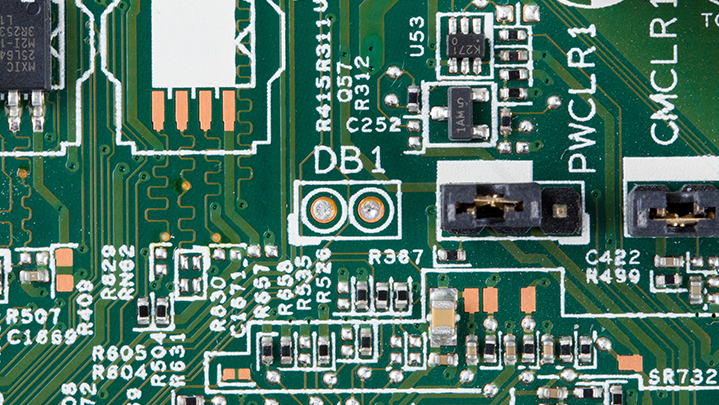

The equipment combines a powerful imaging system with flexible and sophisticated logic algorithms to comprehensively inspect various defects, including wrong part, missing part, reverse, offset, various solder joint defects, and foreign object, duplicate, and solder ball on the entire PCB.

3D technology enables clear detection of height-related defects. Double-sided AOI inspects both sides of the PCB with SMT and DIP algorithms. SPI solder paste inspection catches most defects early in the production line. The multi-functional conformal coating AOI inspects the quality of UV coating layers and also supports SMT and THT inspection.

* 合作代表客户

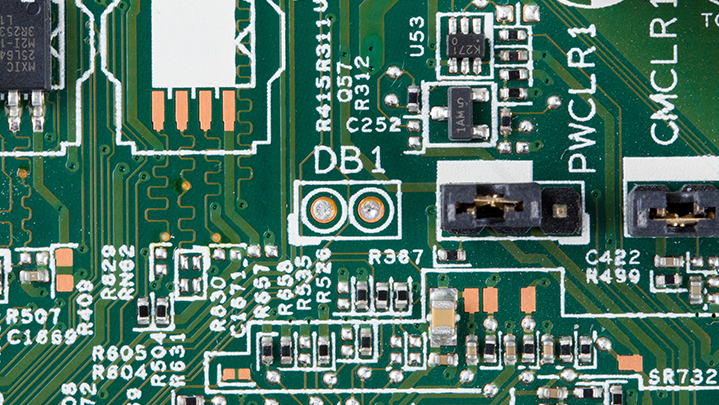

The equipment combines a powerful imaging system with flexible and sophisticated logic algorithms to comprehensively inspect various defects, including wrong part, missing part, reverse, offset, various solder joint defects, and foreign object, duplicate, and solder ball on the entire PCB.

3D technology enables clear detection of height-related defects. Double-sided AOI inspects both sides of the PCB with SMT and DIP algorithms. SPI solder paste inspection catches most defects early in the production line. The multi-functional conformal coating AOI inspects the quality of UV coating layers and also supports SMT and THT inspection.

* 合作代表客户