Redefine Vision & Intelligence

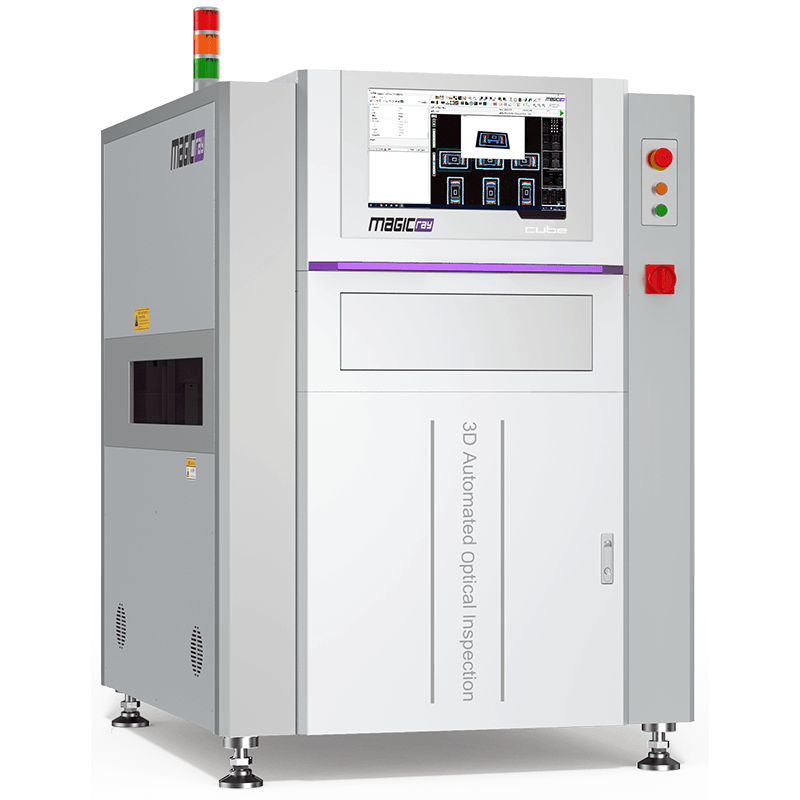

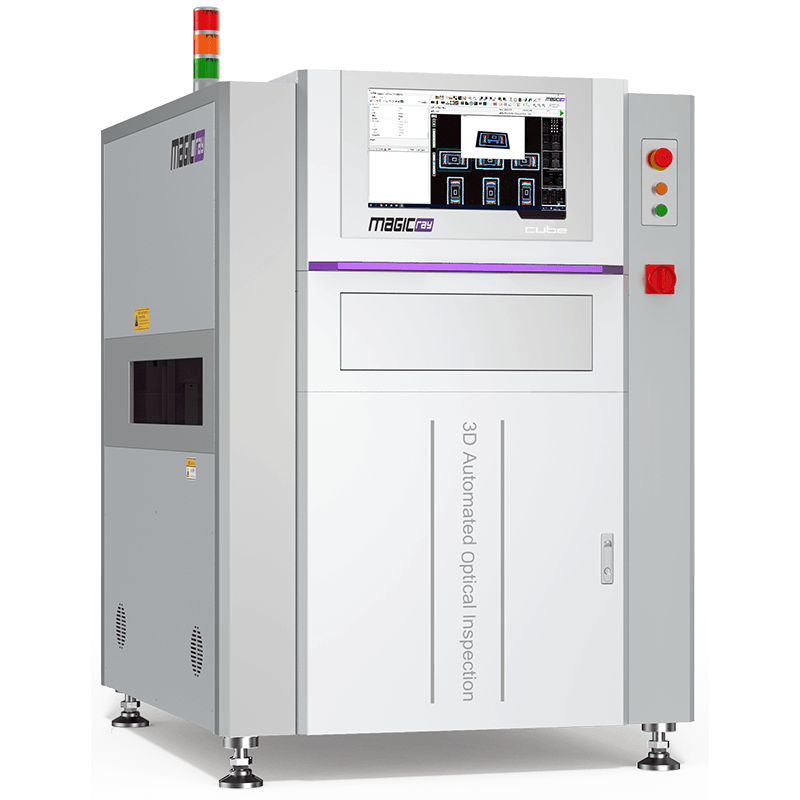

Cube Series

Cube Series

Rich algorithm, the combination of 3D, Al and color feature algorithms to optimize the detection rate of the defects.

Multiple positioning methods to locate the component precisely. Intelligently compensate for board warpage and detect defects on black components on black board.

Adapts to different color PCBs, effectively detect both black and white boards.

Marble platform, dual-drive plus motion control card ensure industry-leading inspection speed.

Ultra-high range 3D reconstruction technology, capable of measuring components up to 35mm height.

The powerful combination of three-point check software and SPC data analysis quickly identifies the root cause of defects.

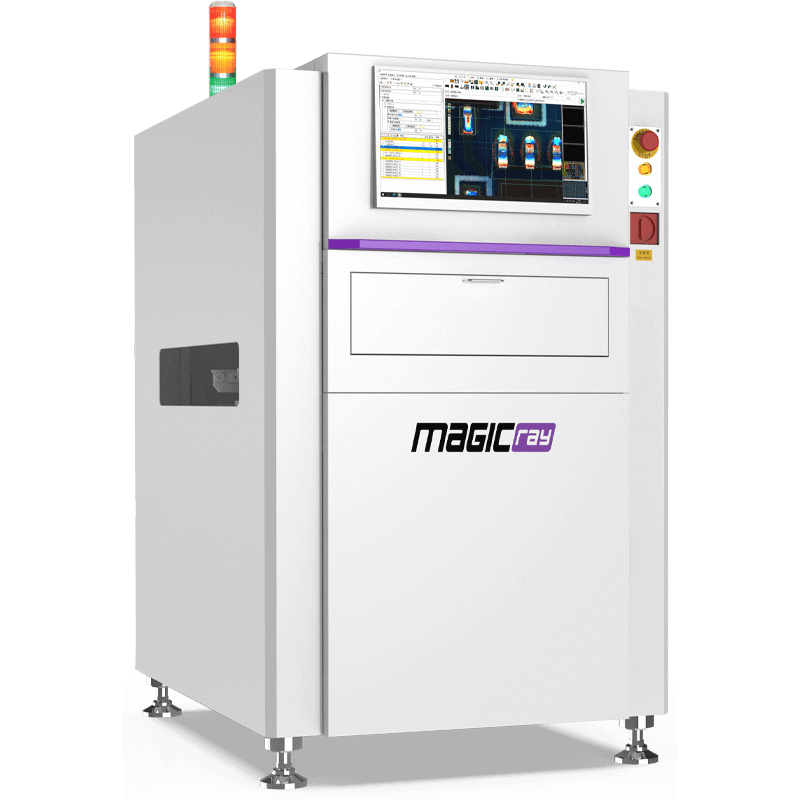

V5000 Series

V5000 Series

Use of granite platform and telecentric lens.

Powerful software algorithm makes inspection very reliable.

Automatic compensation for board warpage or PCB deformed by high temperature effects make our machine just as suitable for FPC.

SPC data analysis helps to improve process quality.

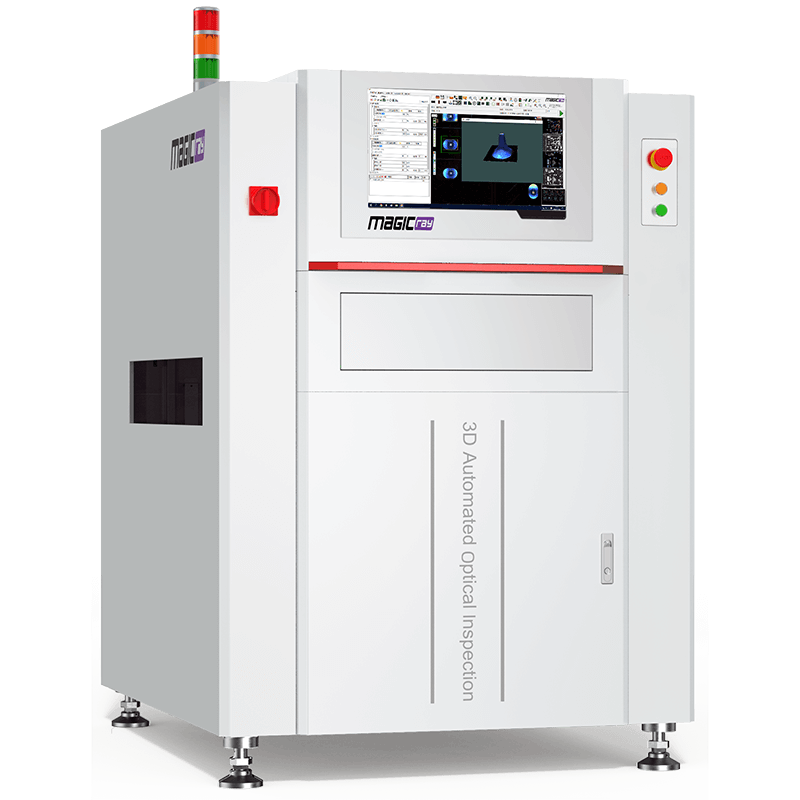

Cube Series

Cube Series

Rich algorithm, the combination of 3D, Al and color feature algorithms to optimize the detection rate of the defects.

Multiple positioning methods to locate the component precisely. Intelligently compensate for board warpage and detect defects on black components on a black board.

Adapts to different color PCBs, and effectively detects both black and white boards.

Marble platform, dual-drive plus motion control card ensure industry-leading inspection speed.

Ultra-high range 3D reconstruction technology, capable of measuring components up to 35mm in height.

The powerful combination of three-point check software and SPC data analysis quickly identifies the root cause of defects.

V5000 Series

V5000 Series

Use of granite platform and telecentric lens.

Powerful software algorithm makes inspection very reliable.

Automatic compensation for board warpage or PCB deformed by high temperature effects make our machine just as suitable for FPC.

SPC data analysis helps to improve process quality.

VS7300 Series

VS7300 Series

Synchronous positioning of upper and lower parts, asynchronous interlocking for image retrieval, and simultaneous completion of double-sided detection to avoid interference from lighting, saving factory space.

Equipped with high-speed industrial cameras and motion control cards, achieving industry-leading inspection speed and stability.

Ultra-high measurement range and clearance, coupled with dual-sided Z-axes, suitable for wave soldering production lines, effective inspection of THT floating height defects.

Rich feature algorithms:3D+Al+color extraction, flexibly satisfy SMT and THT Inspection demands.

Specialized algorithm for dip soldering joint: accurate measurement of pin height, and effective inspection of defects like missing pins or no protrusion leads.

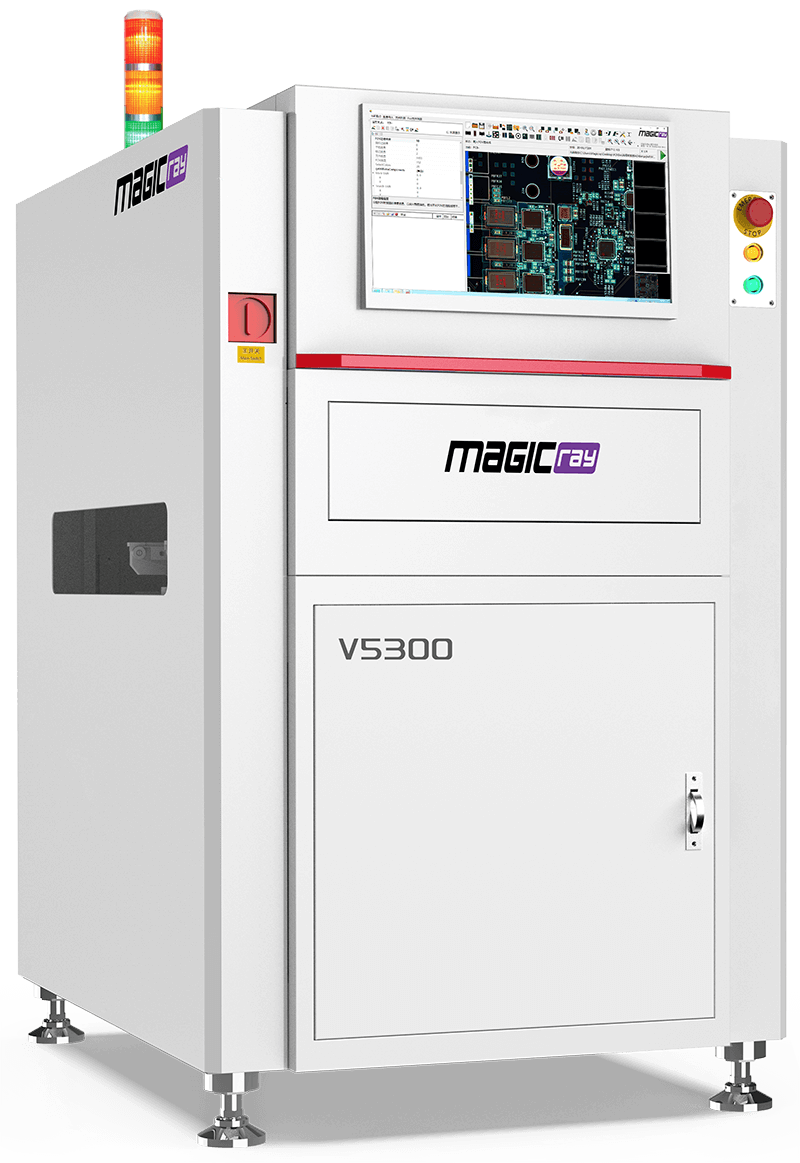

V5300 Series

V5300 Series

A unique feature of inspecting the top and bottom side of PCBs simultaneously simplifies the process and saves production space.

Roller type conveyor can be selected vs the standard Belt type, the former is more resistant to high temperature, dirt and heavy loads.

Magic-ray's advanced Solder Pad Positioning and FOV-assisted Positioning algorithms improve the inspection capability of solder joints..

Dedicated algorithm for CPU pins, accurately captures various defects such as Pin Bending, Pin Deformation and Missing Pins.

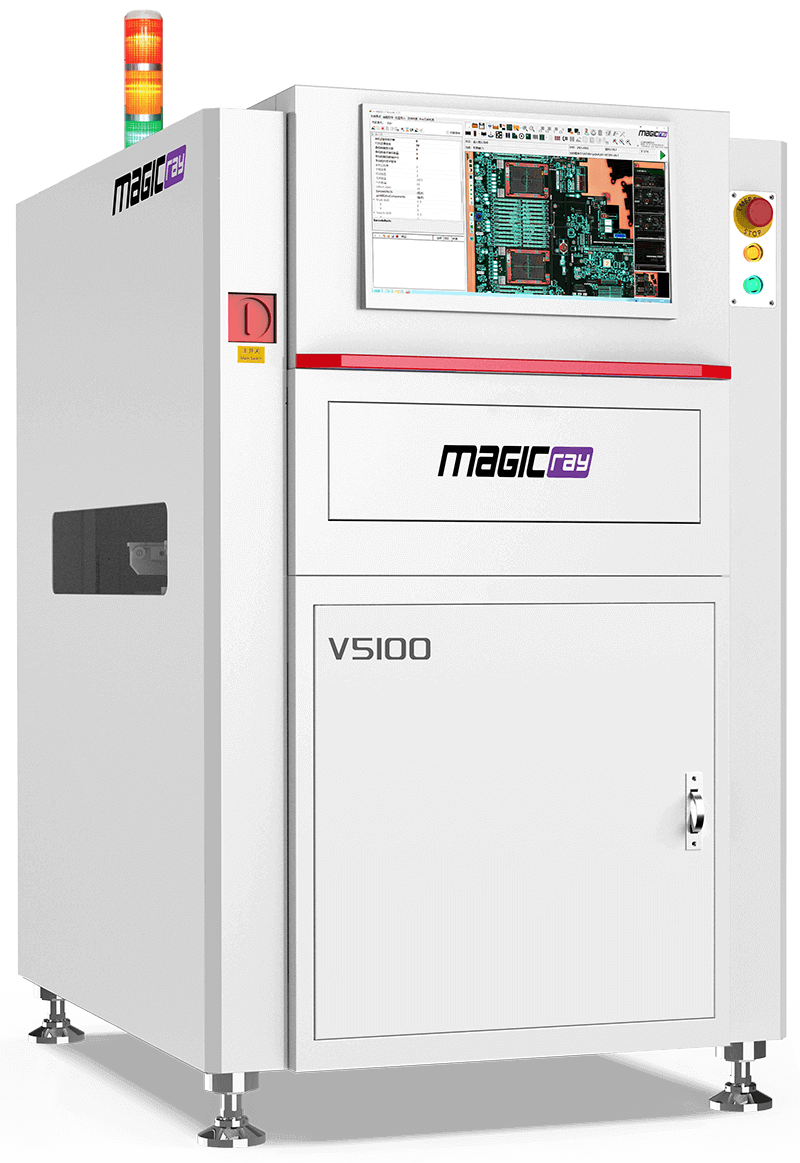

V5100 Series

V5100 Series

Abundant algorithms, capable of detecting SMT, wave soldering and odd-form components.

AI-powered simplified programming, one-click generation of components and solder joint inspection windows, automatic identification of component polarity.

Belt or roller drive, easy to deal with oversized and overweight PCBs.

Wide range of applications, can be flexibly used for pre-reflow or post-reflow inspection.

Spacious base design, universal compatibility for most bottom fixture return conveyors.

VF5100/VF5300

VF5100/VF5300

Five-sided inspection, with full coverage around the components.

Automatically draw side adhesive contour lines to clearly distinguish adhesive boundaries.

Slide the mouse to view the percentage of climbing height at any position on the side of the component.

Save images of five sides and test data to facilitate process review.

Optional thickness measurement function to achieve inline measurement of adhesive thickness.

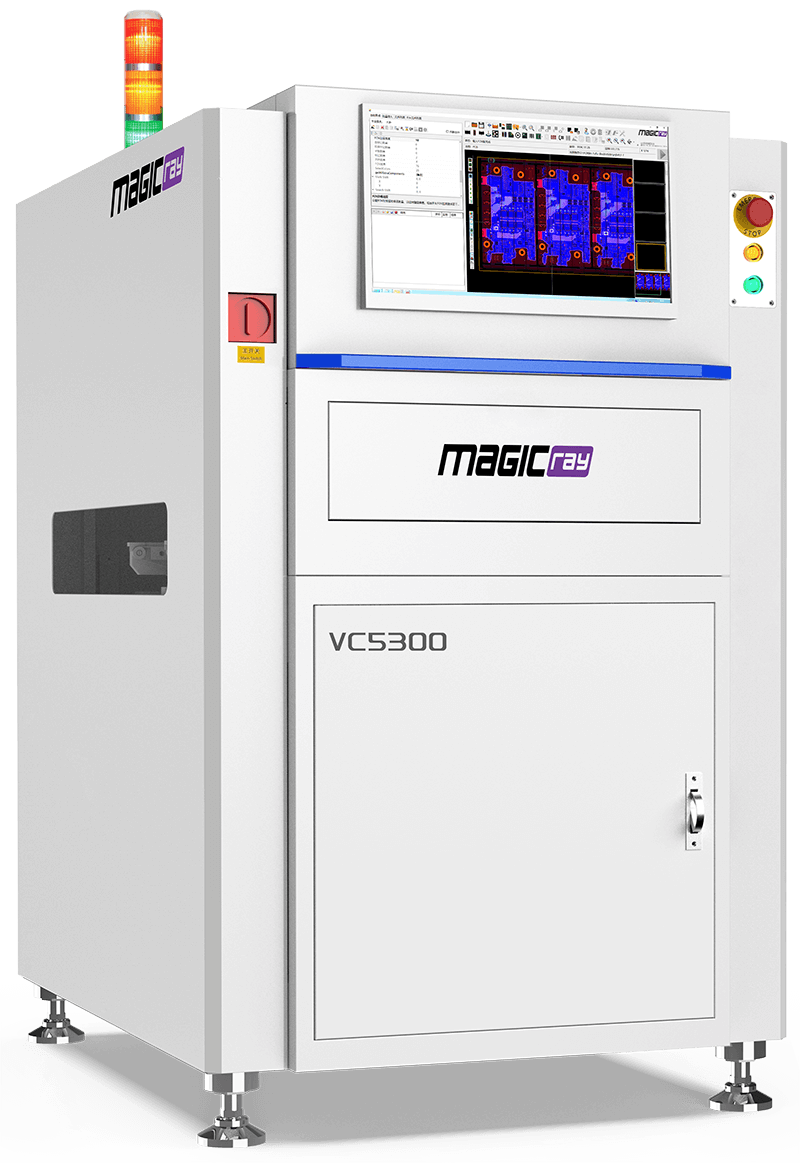

VC5100/VC5300 Series

VC5100/VC5300 Series

Usage of high-brightness UV lighting, easily distinguishes the coating containing phosphor.

Support cross-FOV whole-board programming and CAD programming, adapting to various inspection scenarios.

Support Single-side or Double-side inline automatic inspection of conformal coating.

Coating Thickness Measurement is optional, realizing real-time high-precision thickness measurement.

Optional intelligent Al algorithm optimizes detection on bubble defects.